Galvanic Corrosion is an

electro/chemical process in which one metal corrodes preferentially

to another when both metals are in electrical contact, in the

presence of an electrolyte. wikipedia.com

In plumbing the process takes place

when pipes, made of different metals, are joined together. Most often

this is copper and galvanized steel water pipe. Water in the system,

along with minerals and various chemicals contained in drinking

water, provides the electrolyte bath. The most common occurrence is

at water heaters where copper water pipe connects to the steel tank

of the heater.

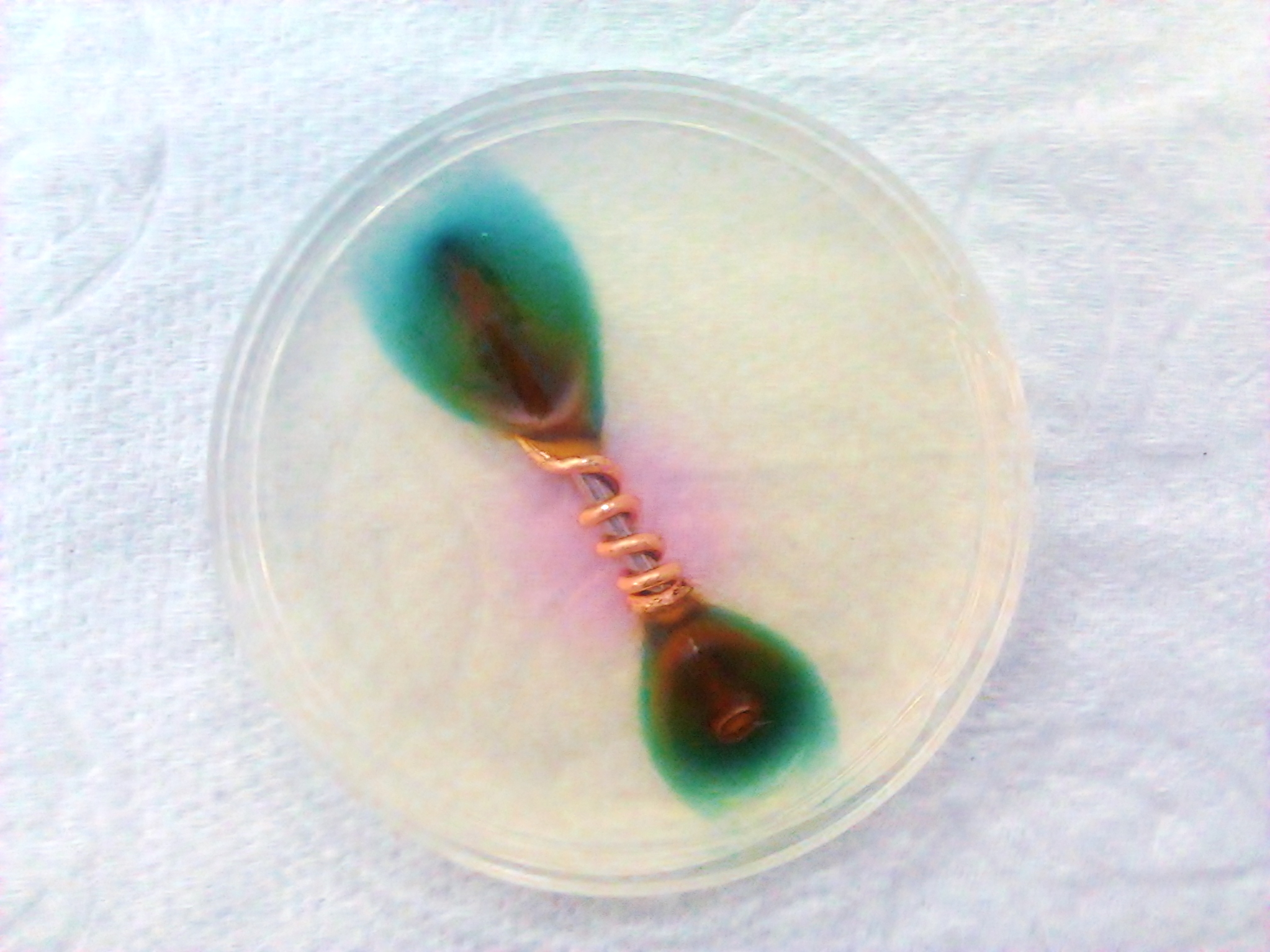

As you can see in the photo, the iron

nail is being corroded by the copper wire. In galvanic corrosion the

greater the difference of electro-potentials of the metals the faster

corrosion takes place. In the case of copper and galvanized steel the

difference is quite large, even greater than the iron nail shown. In

situations where copper pipes are directly connected to steel pipes

the steel corrodes quickly.

If we have a water heater, which has a

steel tank with two threaded steel outlets, and copper adapters are

screwed directly into those outlets, it is only a matter of time

before the steel corrodes and the tank begins to leak. When the tank

begins to leak there is no choice but to replace the heater.

So why does anyone connect copper pipes

to a steel water heater tank, and how can we make a connection that

will not cause corrosion?

People make direct connections because

they don't understand galvanic corrosion and/or they don't know the

proper way to connect dissimilar types of pipe. The goal is simply to

keep the dissimilar metals away from each other. Teflon tape or pipe

joint compound on the threads will not accomplish this! We need

better isolation. In the picture below you can see that the copper

adapters which were connected directly to the water heater tank have

been removed and replaced by isolating nipples.

The nipples used in the tank are

“dielectric nipples” made of a non-conductive allow and lined

with plastic. This breaks the electrical bond between the dissimilar

metals and also with the water (electrolyte) inside the pipe. From

there I used a heavy brass push-on fitting to eliminate the need of

soldering.

We could also use a dielectric union.

They use a rubber gasket between the union faces and a plastic collar

between the union nut and the copper part of the union to isolate the

dissimilar metals from contact. The goal again is to keep the

dissimilar metals and the electrolyte bath provided by the water

inside the pipe from making contact.

We have looked at water heaters, but

anywhere copper meets steel is a potential for corrosion. In older

homes and buildings galvanized water mains are often replaced or

repaired using copper tubing without proper isolation. This only

causes already corroded pipes to corrode faster. Anywhere copper or

brass meets steel dielectric nipples and/or fittings should be used

for the transition.

As you can see in the picture above it

is not a difficult nor expensive procedure to properly isolate your

steel water heater tank from the copper water lines attached to it,

and it could prevent the very costly need to replace a corroded and

leaking water heater. Dielectric nipples are available in pairs for

under $10 (USD) and push-on fittings are around $6 (USD) each, so for

less than twenty-five bucks you can save yourself from having a

corroded water heater. That replacement could run over a grand!